1. Over cutting optimization function: The selected CAM software systematically optimizes the physical over cutting condition of the lathe, largely restoring the contour of the pattern, bringing users good actual cutting results.

2. Intelligent worktable compensation function: After high-precision spacing tester testing the flatness of the worktable, the system adjusts the flatness in real time to ensure high-quality cutting results.

3. Front and back cutting function: Use the workbench inspection function to complete the intelligent front and back pattern cutting function.

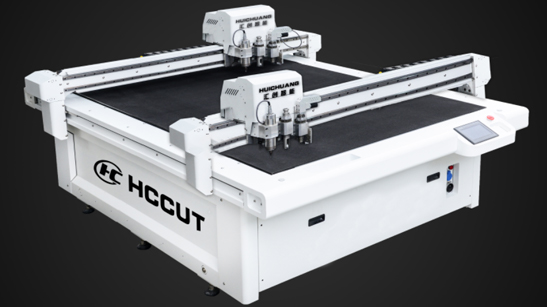

4. Automatic tool setting function: A fast and convenient fully automatic tool setting system that uses fiber optic laser sensors to check the unfolding degree of the lathe, enhancing the efficiency of tool setting work.

5. Lathe quick change module: A simplified tool holder quick change system makes practical operation easier and faster.

6. Multi task cyclic cutting, intelligent adsorption hardware configuration.

7. The entire cutting operation process is odorless, dust-free, and does not pose a health hazard to workers, meeting environmental protection standards.

8. Low carbon, environmental protection, zero pollution, and no radiation enhance the competitiveness of the industry.

查看分類